|

|

Our pre-sale service includes:

One-on-one consultation to learn your detailed needs

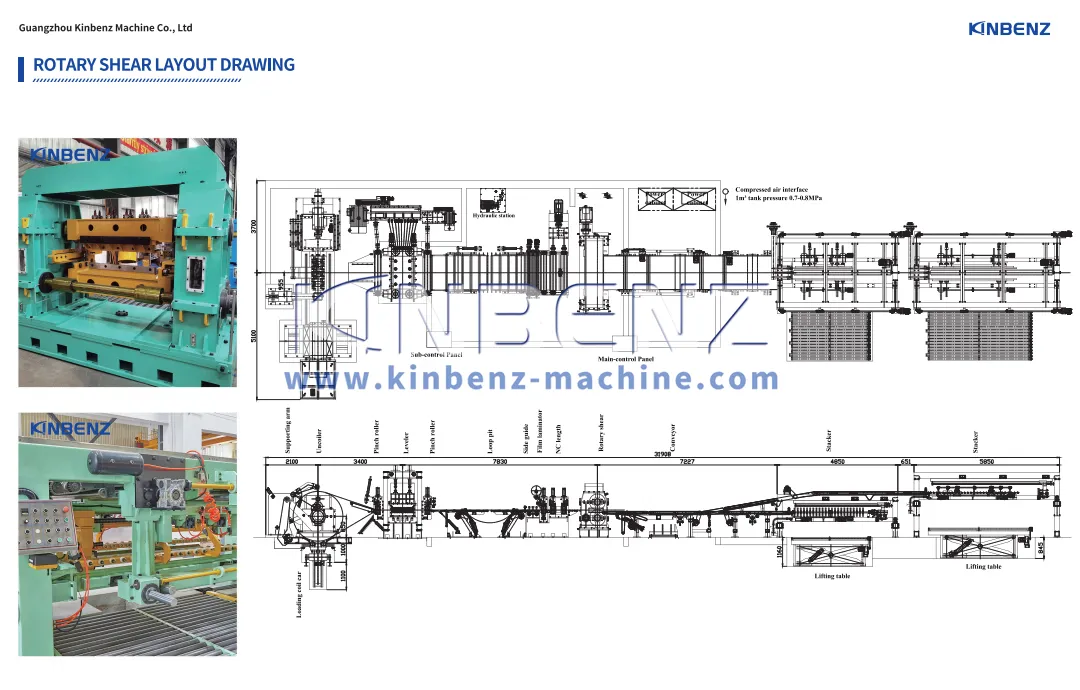

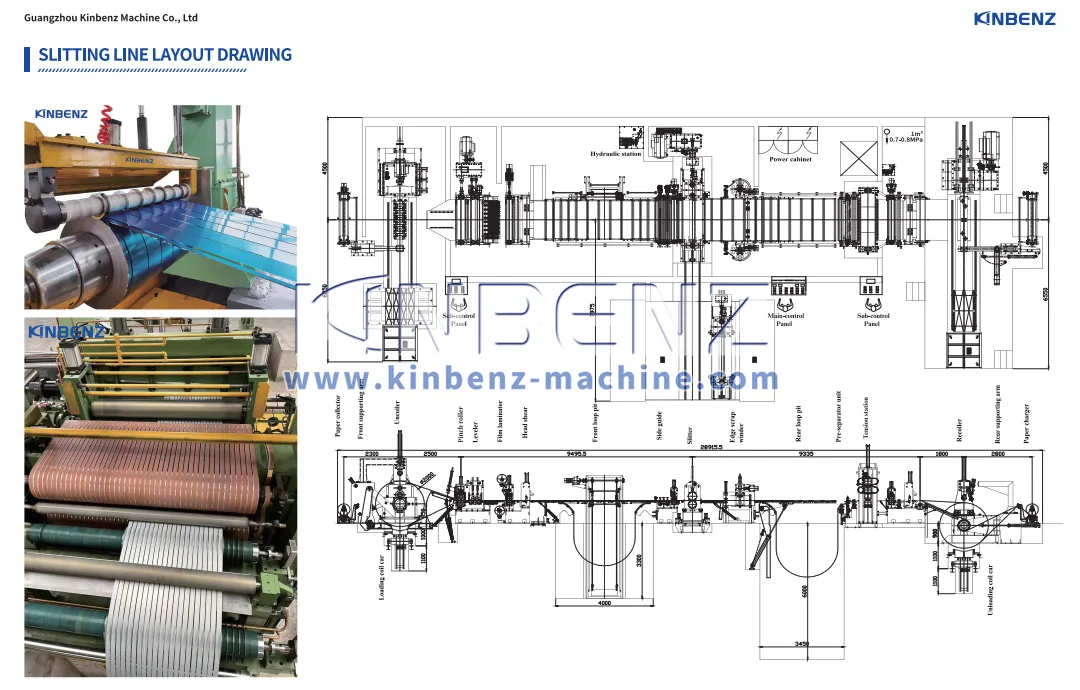

Technical proposal with layout suggestions and production flow design

Clear offer quotation and delivery timeline

A right investment starts before the sale

We can customize:

● Machine layout with different size or extra components ( like film laminator, paper collector, etc.)

● Slitting & Cutting width tolerance

● Line speed

● Line color

● Electrical control systems brand (Siemens or other european brands)

● OEM

With our R&D department and in-house engineering team, we can provide full technical drawings for approval before production, ensuring a smooth process from design to delivery.

To ensure every machine meets strict quality and performance standards, we conduct thorough testing before shipment.

If customers can provide metal coil samples, we will carry out a full material test run to vertify cutting/slitting performance, accuracy, and stability.

If the material is not available, we perform a dry run without material to check all mechanical movements, electrical circuits, and system integrations, including motors, sensors, PLC controls, and more.

We invite clients to:

Visit our factory for on-site inspection, or

Join a online meeting inspection session to observe the test process remotely.

All testing procedures are documented, and we only proceed to packaging after your final approval.

On-site installation and commissioning by experienced engineers to your address

Operator training and mainenance guidance

1-year warranty for every production line

Our engineers have handled overseas installation across various reigons, ensuring efficient machine strat-up and staff training on location.

Kinbenz was established in 1990, born from a vision to bring precision, reliability, and innovation to the field of metal coil processing machinery. With over three decades of experience, we have grown from a modest workshop into a comprehensive high-tech enterprise, integrating R&D, production, customization, and global sales.

From the very begining, Kinbenz has been committed to exceeding industry standards. Every part we produce - from mechanical frames to electronic control systems - must meet or surpass national and international industrial standards. Our quality control processes are rooted in precision and consistency, ensuring long-term value for every customer.

Our core technical strength comes from the original Taiwan Tengaki process, which our R&D team has deeply inherited and refined. By combining this legacy with real-world customer feedback and ongoing technological advancement, Kinbenz has developed machinery that now surpasses the performance and design level of traditional equipment.

Over the years, we've expanded our facilities to three manufacturing plants equipped with advanced CNC machining centers, welding workshops, and precision testing tools. We have built a strong technical team - many of whom have over 15 years of hands-on experience -and continuously invested in research, innovation, and customer-orinted engineering.

With a growing global reputation and custoemrs in over 50 countries, Kinbenz continues to walk ahead with long-term trust, steady growth, and a relentless pursuit of quality.

Our team produly owns over 200 skilled professional is each different areas, each contributing to our reputation as a reliable and innovative manufacturer in the metal coil processing industry.

Operate across three independent manufacturing plants, allowing us to efficiently manage both standard production and highly customized projects for overseas clients.

Integrated production system includes:

● CNC Machining Workshop - for precision part processing

● Welding Workshop - ensuring strong and accurate structural components

● Assembly Workshop - where mechanical and electrical systems are assembled and integrated

● Painted Workshop - providing durable industrial coatings and clean finishes

● Quality Control Department - enforcing strict inspection at every production stage

Experienced engineers and technicians work closely across departments, ensuring that every detail is controlled in-house. This gives full control over lead times, performance accuracy, and product consistency.

In addition to production, our proactive and experienced sales and service team, ready to provide technical support, quotation offer, and after-sales assistance in both domestic and international markets.