|

|

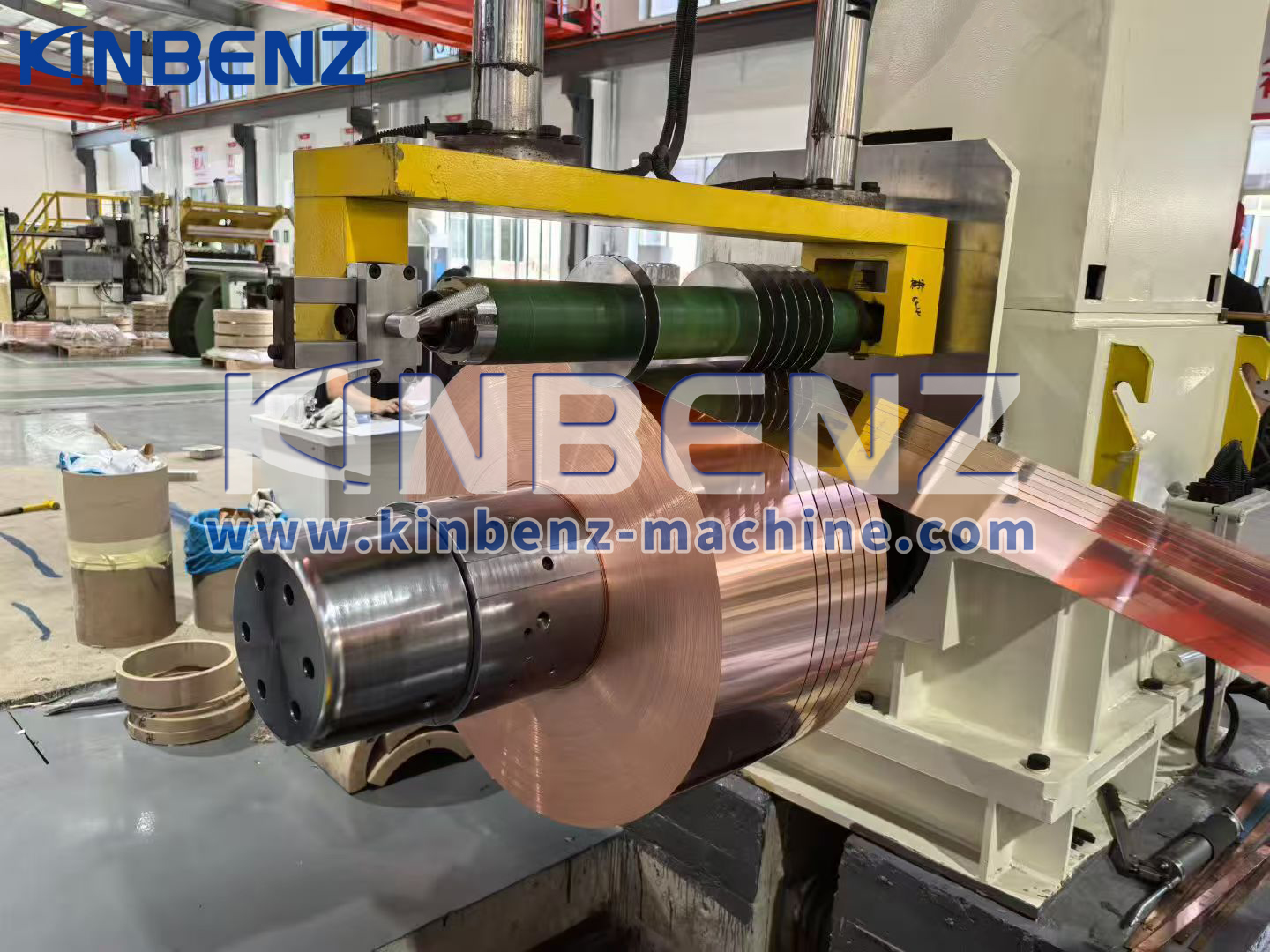

Simple Structure Slitting Line - Cost-Effective Solution for Thin and Narrow Metal Coil Processing

2025-11-08

What Is Simple Structure Slitting Line?

A simple structure slitting line is a compact version of standard slitting line, specifically developed for processing light-gauge coils ( 0.3-3.0mm thickness) and narrow coil width ( such as around 500mm).

While the configuration remains similar to standard slitting line, the structure and power requirements are simplified, making it more economical and easier to operate.

A complete simple slitting line typically includes:

- Uncoiler

- Pinch roller

- Slitter

- Scrap winder

- Tension station

- Recoiler

Despite being "simple", this configuration still allows for efficient and precise coil slitting for materials such as stainless steel, galvanized steel, aluminum and copper.

Main Features of KINBENZ Simple Structure Slitting Line

- Compact and Cost-Effective

Designed with fewer driving components and simplified power transmission, this line offers lower investment costs and reduced maintenance needs.

- Stable Performance for Thin Coils

Ideal for preocessing light-gauge materials where high power is unnecessary. The simplified driven system ensures smooth and reliable operation.

- Customizable Design

KINBENZ supports customization based on your coil width, thickness range, and material type - providing flexibility without necessary cost.

- Precision Slitting Quality

The line uses high-quality slitting blades and precise tension control, ensuring clean edges and accurate widths even for thin metal strips.

- User-Friendly Operation

With a simplified control system, operators can quickly set up and montior the entire process, make it suitable even for first-time users.

Applications

Slitting line is widely used in industries that requires small-batch production or light material processing, including:

- Home appliance manufacturing

- Metal decoration and finishing

- Electrical component production

- Aluminum and copper foil slitting

Its versatility and affordability make it a popular choice among small-to-medium manufacturers who need stable, efficient performance without the complexity of a full-size line.

Why Choose Slitting Line from KINBENZ?

At KINBENZ, every machine - from the simplest configuration to the most advanced automatic system - is built with precision and attention to detail.

Our simple structure slitting line combine:

- High-quality machine craftsmanship

- Reliablie tension and edge control

- Customizable design for your coil specifications

- Lower energy consumption for cost-efficient operation

Whether you're starting a new coil processing business or expanding your capabilities, KINBENZ can provide a right-sized solution that matches your budget and production goals.

FAQ: About Simple Structure Slitting Line

Q1: What is the main difference between a simple structure slitting line and a standard slitting line?

A: The simple structure version uses fewer drive components, simplified tension systems, and typically handles narrower and thinner coils (500–650mm width, 0.3–3.0mm thickness). It offers a more cost-effective solution without sacrificing basic functionality.

Q2: What materials can it process?

A: It's suitable for stainless steel, galvanized steel, aluminum, copper, and similar light metal coils.

Q3: What is the typical running speed?

A: The line operates smoothly with adjustable speed, generally up to 60m/min, depending on coil type and thickness.

Q4: Can the line be customized?

A: Yes. KINBENZ supports customized configurations — including coil width, thickness range, slitter knife setup, and recoiler design — based on each client's needs.

Q5: Is it suitable for large-volume production?

A: The simple structure line is mainly intended for light- and medium-duty production. For high-volume or heavy-gauge material processing, a standard or heavy-duty slitting line would be recommended.

Conclusion

The Simple Structure Metal Coil Slitting Line by KINBENZ combines efficiency, economy, and reliability — the perfect balance for businesses that value cost performance and flexibility.

With its compact footprint, low energy consumption, and full essential functions from uncoiling to recoiling, it's the smart choice for processing thin and narrow metal coils efficiently.

At KINBENZ, we're committed to providing tailored coil slitting solutions to meet the diverse needs of our global customers — from simple lines to fully automatic high-speed systems.

What Is Simple Structure Slitting Line?

A simple structure slitting line is a compact version of standard slitting line, specifically developed for processing light-gauge coils ( 0.3-3.0mm thickness) and narrow coil width ( such as around 500mm).

While the configuration remains similar to standard slitting line, the structure and power requirements are simplified, making it more economical and easier to operate.

A complete simple slitting line typically includes:

- Uncoiler

- Pinch roller

- Slitter

- Scrap winder

- Tension station

- Recoiler

Despite being "simple", this configuration still allows for efficient and precise coil slitting for materials such as stainless steel, galvanized steel, aluminum and copper.

Main Features of KINBENZ Simple Structure Slitting Line

- Compact and Cost-Effective

Designed with fewer driving components and simplified power transmission, this line offers lower investment costs and reduced maintenance needs.

- Stable Performance for Thin Coils

Ideal for preocessing light-gauge materials where high power is unnecessary. The simplified driven system ensures smooth and reliable operation.

- Customizable Design

KINBENZ supports customization based on your coil width, thickness range, and material type - providing flexibility without necessary cost.

- Precision Slitting Quality

The line uses high-quality slitting blades and precise tension control, ensuring clean edges and accurate widths even for thin metal strips.

- User-Friendly Operation

With a simplified control system, operators can quickly set up and montior the entire process, make it suitable even for first-time users.

Applications

Slitting line is widely used in industries that requires small-batch production or light material processing, including:

- Home appliance manufacturing

- Metal decoration and finishing

- Electrical component production

- Aluminum and copper foil slitting

Its versatility and affordability make it a popular choice among small-to-medium manufacturers who need stable, efficient performance without the complexity of a full-size line.

Why Choose Slitting Line from KINBENZ?

At KINBENZ, every machine - from the simplest configuration to the most advanced automatic system - is built with precision and attention to detail.

Our simple structure slitting line combine:

- High-quality machine craftsmanship

- Reliablie tension and edge control

- Customizable design for your coil specifications

- Lower energy consumption for cost-efficient operation

Whether you're starting a new coil processing business or expanding your capabilities, KINBENZ can provide a right-sized solution that matches your budget and production goals.

FAQ: About Simple Structure Slitting Line

Q1: What is the main difference between a simple structure slitting line and a standard slitting line?

A: The simple structure version uses fewer drive components, simplified tension systems, and typically handles narrower and thinner coils (500–650mm width, 0.3–3.0mm thickness). It offers a more cost-effective solution without sacrificing basic functionality.

Q2: What materials can it process?

A: It's suitable for stainless steel, galvanized steel, aluminum, copper, and similar light metal coils.

Q3: What is the typical running speed?

A: The line operates smoothly with adjustable speed, generally up to 60m/min, depending on coil type and thickness.

Q4: Can the line be customized?

A: Yes. KINBENZ supports customized configurations — including coil width, thickness range, slitter knife setup, and recoiler design — based on each client's needs.

Q5: Is it suitable for large-volume production?

A: The simple structure line is mainly intended for light- and medium-duty production. For high-volume or heavy-gauge material processing, a standard or heavy-duty slitting line would be recommended.

Conclusion

The Simple Structure Metal Coil Slitting Line by KINBENZ combines efficiency, economy, and reliability — the perfect balance for businesses that value cost performance and flexibility.

With its compact footprint, low energy consumption, and full essential functions from uncoiling to recoiling, it's the smart choice for processing thin and narrow metal coils efficiently.

At KINBENZ, we're committed to providing tailored coil slitting solutions to meet the diverse needs of our global customers — from simple lines to fully automatic high-speed systems.