|

|

What Is the Function of Trimming Shear in Cut to Length Line

2025-11-04

What is a Trimming Shear?

Trimming shear, also know as edge trimming shear machine or side trimmer, is typically positioned after the leveler and before the main shear in Cut to Length Line.

Its main taks is to trim both sides of the uncoiled strips, removing uneven, cracked, or deformed edges from the raw coil. These imperfections often result from upstream rolling or slitting processes.

By removing these irregular edges, the trimming shear ensures that the strip:

- Has a clean and uniform edge profile

- Acheives precise final width tolerance

- Maintains improved sheet flatness and edge quality

Key Functions of Trimming Shear in Cut to Length Line

1. Edge Quality Improvement

Trimming shear removes any burrs, cracks, or oxidation along the coil edges, ensuring smooth and consistent sheet edges.

This is especially important for materials used in automotive, construction, and appliance industries, where edge quality affects both safety and aesthetic apperance.

2. Accurate Width Control

After trimming, strip width can be adjusted to the exact required size.

For example, if a coil has an original width of 1250mm but requires 1220mm final sheets, the trimming shear will cut 15mm off each side to achieve the desired dimension.

3. Preparation for High-Precision Cutting

Trimming ensures the coil edges are perfectly aligned before entering the main shear. This alignment allows the main shear to perform accurate lengthwise cutting without deviation, maintaining parallelism and rectangular accuracy of the final sheets.

4. Reducing Waste and Downstream Problems

Coils with poor edge quality can cause issues during stacking or further processing (like welding or painting)

Using trimming shear early in the process prevents uneven stacking, edge overlap, or damage to downstream equipment, thus improving overall efficiency and reducing rework costs.

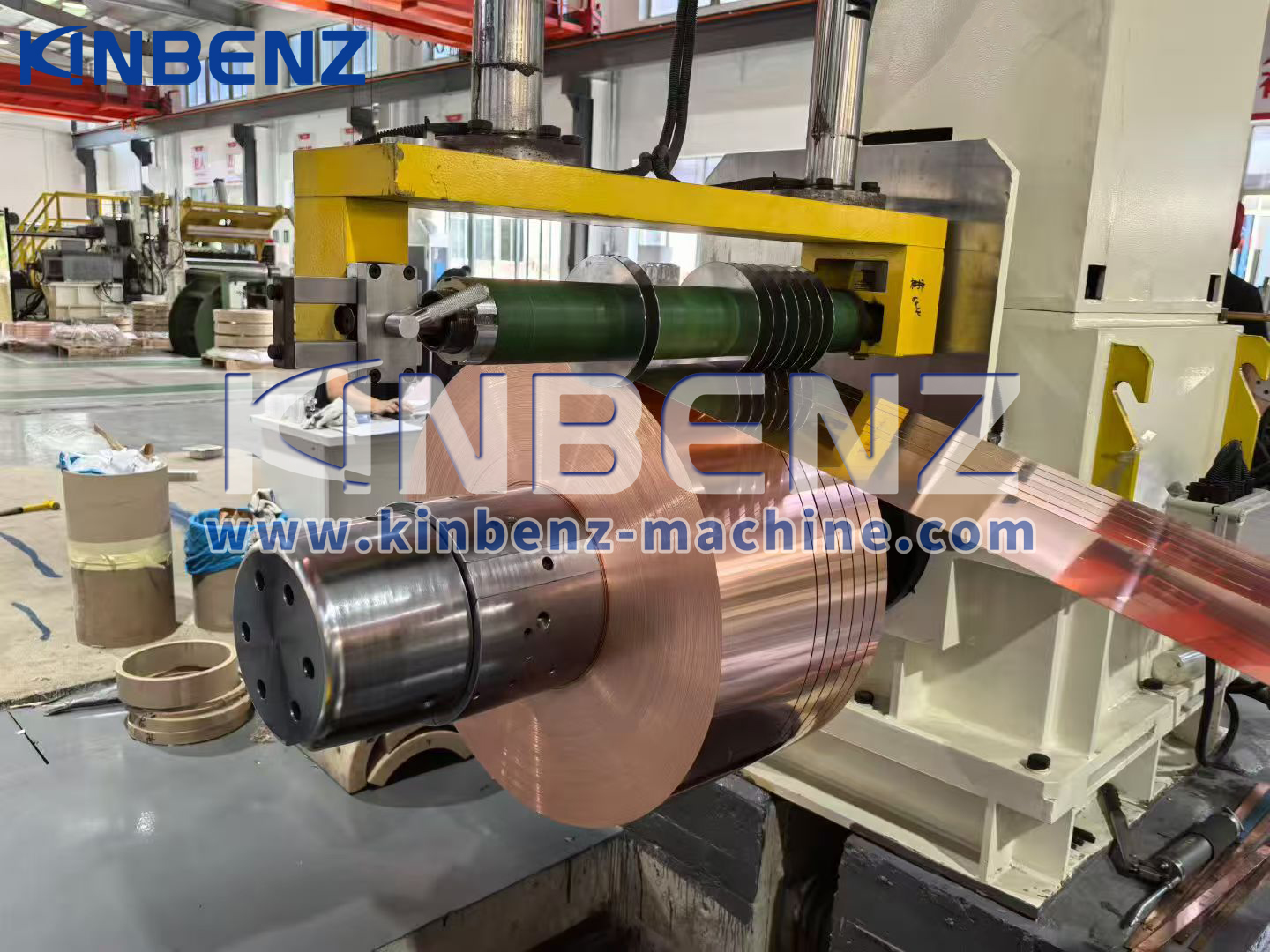

Structure and Operation of Trimming Shear

Standard trimming shear in cut to length line consists of:

- Two upper and lower rotary blades (one set per side)

- Edge scrap collection or winding system ( to collect trimmed edges)

- Adjustable blade positioning system

During operation:

- The coil passes through the trimming shear

- Each blades set removes the excess material from one edge

- The scrap is collected by scrap winder or belt conveyor to keep the line clean and continuous

Applications Across Industries

Trimming shears are vital in processing carbon steel, stainless steel, aluminum and so on.

You 'll commonly find them in Cut to Length Line serving:

- Automotive body panel production

- Electrical appliance manufacturing

- Construction sheet and roofing materials

- Metal furniture and decorative panels

Trimming shear guarantee that each sheet meets strict dimensional and surface quality requirements.

KINBENZ Trimming Shear Highlights

At KINBENZ, our trimming shear designs are tailored to ensure durability, accuracy, and ease of maintenance.

Key features include:

- Heavy-duty steel welded frame for vibration - free operation

- Precision rotary blades with long service life

- Automatic scrap rewinding system for efficient edge waste handling

- Optional motorized width adjustment for fast and precise setup

These advantages make our trimming shear units ideal for both standard and high-precision cut to length lines.

FAQ: About Trimming Shear in Cut to Length Line

Q1: Do all cut to length lines require a trimming shear?

A: Not necessarily. If the incoming coils are already well slit and have clean edges, trimming shear may not be required. However, for high-precision or export-grade products, trimming is highly recommended.

Q2: How is the trimmed scrap handled?

A: Scrap is collected by automatic edge scrap winders, ensuring a clean workplace and smooth continuous production.

Q3: How often should the trimming blades be maintained or replaced?

A: It depends on material type and production volume.

Trimming shear is far more than an optional accessory - it's a key component for ensuring dimensional precision, surface quality, and process stability in any cut to length line.

By integrating a high-performance trimming system, manufacturers can reduce material waste, enhance final product quality, and ensure smooth downstream production.

At KINBENZ, we provide tailored trimming shear solutions designed for your specific coil materials and production goals - helping you acheive precision and efficiency in every sheet you produce.

What is a Trimming Shear?

Trimming shear, also know as edge trimming shear machine or side trimmer, is typically positioned after the leveler and before the main shear in Cut to Length Line.

Its main taks is to trim both sides of the uncoiled strips, removing uneven, cracked, or deformed edges from the raw coil. These imperfections often result from upstream rolling or slitting processes.

By removing these irregular edges, the trimming shear ensures that the strip:

- Has a clean and uniform edge profile

- Acheives precise final width tolerance

- Maintains improved sheet flatness and edge quality

Key Functions of Trimming Shear in Cut to Length Line

1. Edge Quality Improvement

Trimming shear removes any burrs, cracks, or oxidation along the coil edges, ensuring smooth and consistent sheet edges.

This is especially important for materials used in automotive, construction, and appliance industries, where edge quality affects both safety and aesthetic apperance.

2. Accurate Width Control

After trimming, strip width can be adjusted to the exact required size.

For example, if a coil has an original width of 1250mm but requires 1220mm final sheets, the trimming shear will cut 15mm off each side to achieve the desired dimension.

3. Preparation for High-Precision Cutting

Trimming ensures the coil edges are perfectly aligned before entering the main shear. This alignment allows the main shear to perform accurate lengthwise cutting without deviation, maintaining parallelism and rectangular accuracy of the final sheets.

4. Reducing Waste and Downstream Problems

Coils with poor edge quality can cause issues during stacking or further processing (like welding or painting)

Using trimming shear early in the process prevents uneven stacking, edge overlap, or damage to downstream equipment, thus improving overall efficiency and reducing rework costs.

Structure and Operation of Trimming Shear

Standard trimming shear in cut to length line consists of:

- Two upper and lower rotary blades (one set per side)

- Edge scrap collection or winding system ( to collect trimmed edges)

- Adjustable blade positioning system

During operation:

- The coil passes through the trimming shear

- Each blades set removes the excess material from one edge

- The scrap is collected by scrap winder or belt conveyor to keep the line clean and continuous

Applications Across Industries

Trimming shears are vital in processing carbon steel, stainless steel, aluminum and so on.

You 'll commonly find them in Cut to Length Line serving:

- Automotive body panel production

- Electrical appliance manufacturing

- Construction sheet and roofing materials

- Metal furniture and decorative panels

Trimming shear guarantee that each sheet meets strict dimensional and surface quality requirements.

KINBENZ Trimming Shear Highlights

At KINBENZ, our trimming shear designs are tailored to ensure durability, accuracy, and ease of maintenance.

Key features include:

- Heavy-duty steel welded frame for vibration - free operation

- Precision rotary blades with long service life

- Automatic scrap rewinding system for efficient edge waste handling

- Optional motorized width adjustment for fast and precise setup

These advantages make our trimming shear units ideal for both standard and high-precision cut to length lines.

FAQ: About Trimming Shear in Cut to Length Line

Q1: Do all cut to length lines require a trimming shear?

A: Not necessarily. If the incoming coils are already well slit and have clean edges, trimming shear may not be required. However, for high-precision or export-grade products, trimming is highly recommended.

Q2: How is the trimmed scrap handled?

A: Scrap is collected by automatic edge scrap winders, ensuring a clean workplace and smooth continuous production.

Q3: How often should the trimming blades be maintained or replaced?

A: It depends on material type and production volume.

Trimming shear is far more than an optional accessory - it's a key component for ensuring dimensional precision, surface quality, and process stability in any cut to length line.

By integrating a high-performance trimming system, manufacturers can reduce material waste, enhance final product quality, and ensure smooth downstream production.

At KINBENZ, we provide tailored trimming shear solutions designed for your specific coil materials and production goals - helping you acheive precision and efficiency in every sheet you produce.